How Flexible Plastics Improve Ruler Longevity

Flexible plastics revolutionize the durability of rulers. When you use a ruler made from these materials, it bends instead of breaking. This flexibility ensures that your ruler lasts longer, saving you money over time. You can rely on these rulers for consistent performance in various tasks. Their ability to withstand pressure without snapping makes them a practical choice for both students and professionals. By choosing flexible plastic rulers, you invest in a tool that combines resilience with cost-effectiveness.

Key Takeaways

- Flexible plastic rulers bend instead of breaking, significantly reducing the risk of damage and ensuring longevity.

- Materials like polypropylene and thermoplastic elastomers (TPE) enhance the durability and usability of rulers, making them ideal for both students and professionals.

- The lightweight and user-friendly design of flexible plastic rulers allows for comfortable handling and precise measurements in various environments.

- Advanced manufacturing techniques, such as injection and extrusion molding, ensure that flexible plastic rulers maintain consistent quality and performance.

- Choosing flexible plastic rulers is a cost-effective investment, as their durability translates into long-term savings and reliable performance.

- Flexible plastic rulers are safe for children, reducing the risk of injury while providing a practical measuring tool for educational settings.

- Regular quality control tests guarantee that flexible plastic rulers meet high standards for flexibility and strength, ensuring customer satisfaction.

Types of Flexible Plastics Used in Rulers

Polypropylene

Properties that enhance flexibility and durability

Polypropylene stands out as a popular choice for making rulers. You will find that its flexibility allows it to bend without breaking. This property makes it ideal for creating durable rulers. Polypropylene also resists chemical reactions, which means it can withstand various environments. Its lightweight nature adds to its appeal, making it easy for you to handle and use.

Common applications in ruler manufacturing

In ruler manufacturing, polypropylene plays a crucial role. Manufacturers often use it to produce standard rulers and specialized measuring tools. You might notice that many school rulers are made from this material. Its ability to maintain shape and resist wear makes it a favorite in educational settings. You can rely on polypropylene rulers for consistent performance over time.

Other Flexible Plastics

Properties and benefits of thermoplastic elastomers

Thermoplastic elastomers (TPE) offer unique benefits in ruler production. You will appreciate their ability to combine the elasticity of rubber with the processability of plastics. This combination results in rulers that are both flexible and strong. TPEs can endure repeated bending and stretching, which enhances their longevity. Their soft texture also provides a comfortable grip, making them user-friendly.

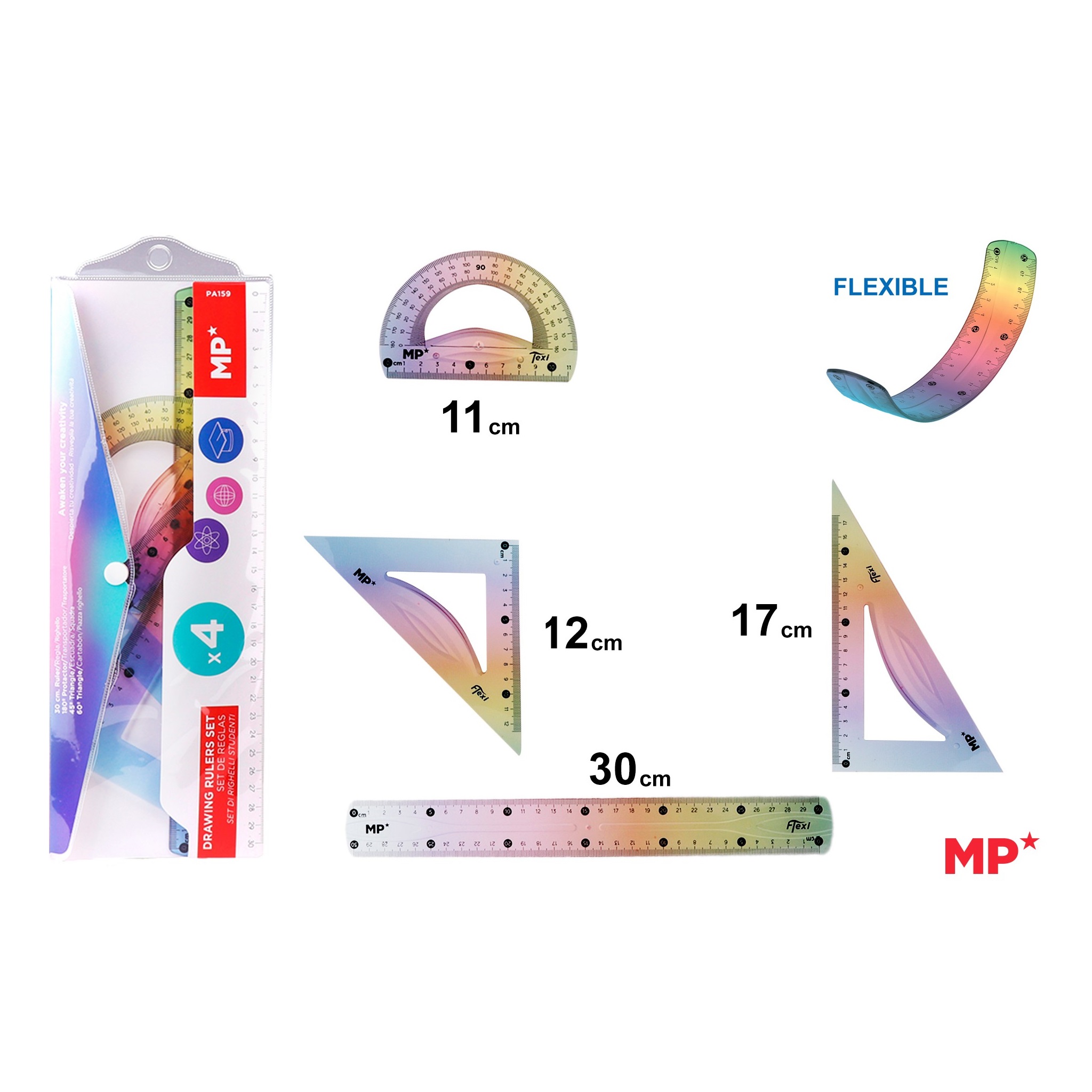

Applications in ruler production, such as in the Drawing Ruler Set of 4

In the production of rulers, TPEs find applications in various products. The Drawing Ruler Set of 4, for instance, uses these flexible plastics to ensure durability and safety. You will find that these rulers can bend without snapping, reducing the risk of injury. This feature makes them suitable for both children and adults. By choosing rulers made with TPEs, you invest in tools that offer both flexibility and reliability.

Benefits of Flexibility in Rulers

Resistance to Breakage

How flexibility reduces the risk of snapping

When you use flexible plastic rulers, you notice a significant reduction in breakage. These rulers bend under pressure instead of snapping. This flexibility acts as a safeguard against sudden breaks. You can apply force without worrying about damaging the ruler. This feature makes flexible plastic rulers a reliable choice for everyday use.

Comparison with traditional rigid materials

Traditional rulers, often made from wood or metal, lack the flexibility of plastic. They tend to snap or crack under stress. You might find that these rigid materials break easily when dropped or bent. In contrast, flexible plastic rulers withstand similar conditions without damage. This durability makes them a superior option for long-term use.

Enhanced Usability

Flexibility in various environments

Flexible plastic rulers adapt well to different environments. Whether you work in a classroom, office, or outdoor setting, these rulers perform consistently. You can use them on uneven surfaces without losing accuracy. Their ability to bend allows you to measure curved objects with ease. This versatility enhances their usability across various tasks.

User-friendly design features

The design of flexible plastic rulers prioritizes user comfort. You will appreciate their lightweight nature, which makes them easy to handle. The smooth edges prevent accidental cuts, ensuring safety during use. Many models feature clear markings for precise measurements. These user-friendly features make flexible plastic rulers an excellent tool for both beginners and professionals.

Manufacturing Process of Flexible Plastic Rulers

Creating flexible plastic rulers involves several precise steps. You will find that manufacturers use advanced techniques to ensure the rulers meet high standards of durability and flexibility.

Molding Techniques

Injection molding process

In the injection molding process, manufacturers inject molten plastic into a mold. This method allows for the creation of complex shapes with high precision. You will notice that this technique produces rulers with consistent thickness and smooth edges. The process ensures that each ruler maintains its flexibility while retaining the necessary strength for everyday use.

Extrusion molding techniques

Extrusion molding involves pushing plastic through a die to form long, continuous shapes. This technique is ideal for producing rulers with uniform cross-sections. You can see that extrusion molding allows for the efficient production of large quantities of rulers. The process ensures that the rulers remain flexible and durable, making them suitable for various applications.

Quality Control Measures

Ensuring durability and consistency

Quality control plays a crucial role in the manufacturing of flexible plastic rulers. Manufacturers conduct rigorous inspections to ensure each ruler meets specific standards. You will find that these measures focus on maintaining the ruler’s durability and consistency. By adhering to strict quality guidelines, manufacturers guarantee that the rulers perform reliably over time.

Testing methods for flexibility and strength

Testing methods assess the flexibility and strength of the rulers. Manufacturers subject the rulers to bending and stretching tests to evaluate their performance. You will appreciate that these tests ensure the rulers can withstand regular use without breaking. By verifying the rulers’ flexibility and strength, manufacturers provide you with a product that meets your expectations for quality and reliability.

Flexible plastics significantly enhance the longevity of rulers. By choosing these materials, you ensure your rulers withstand daily wear and tear. This durability translates into cost savings over time. You benefit from a tool that remains reliable and efficient. Flexible plastic rulers offer a practical solution for both educational and professional settings. Their resilience and user-friendly design make them a valuable addition to your toolkit. Investing in flexible plastic rulers means investing in quality and long-term usability.

FAQ

What makes flexible plastic rulers more durable than traditional ones?

Flexible plastic rulers bend instead of breaking. This flexibility allows them to withstand pressure and rough handling. You will find that they last longer than traditional rigid rulers.

Are flexible plastic rulers safe for children to use?

Yes, flexible plastic rulers are safe for children. Their bendable nature reduces the risk of injury. You can trust them as a safe choice for young users.

How do flexible plastic rulers maintain accuracy?

Manufacturers design flexible plastic rulers with precision. They ensure that the rulers retain their shape and markings. You can rely on them for accurate measurements.

Can I use flexible plastic rulers in outdoor settings?

Absolutely, flexible plastic rulers perform well outdoors. Their resistance to environmental factors makes them suitable for various conditions. You can use them confidently in different environments.

What types of flexible plastics are commonly used in ruler production?

Polypropylene and thermoplastic elastomers (TPE) are popular choices. These materials offer flexibility and durability. You will find them in many high-quality rulers.

How do manufacturers ensure the quality of flexible plastic rulers?

Manufacturers conduct rigorous quality control tests. They check for durability, flexibility, and strength. You can expect consistent performance from these well-tested products.

Are flexible plastic rulers environmentally friendly?

Many flexible plastic rulers use recyclable materials. Manufacturers often focus on sustainability. You can choose eco-friendly options to reduce your environmental impact.

Do flexible plastic rulers come in different sizes and colors?

Yes, flexible plastic rulers are available in various sizes and colors. You can select the ones that best suit your needs and preferences.

How do I care for my flexible plastic ruler to ensure its longevity?

Keep your ruler clean and store it properly. Avoid exposing it to extreme temperatures. You will extend its lifespan by following these simple care tips.

Where can I purchase high-quality flexible plastic rulers?

You can find flexible plastic rulers at office supply stores and online retailers. Look for reputable brands to ensure quality. You will have many options to choose from.

Post time: Dec-19-2024